RCD roller cutters, also called rock roller cutters, rock roller bits, are arranged in a certain pattern on the cutter-head of large diameter Reverse Circulation Drills, also called pile top drill. When RCD cutter-head rotates, RCD roller cutters rotate and bore soil and rock continuously. To suit different geologies and cutter-head, there are 8" and 12" tooth roller cutters, TCI roller cutters, TCI disc roller cutters and cantilever roller cutters to choose from. Click here for a general guide to RCD roller cutter selection. Our RCD roller cutter features:

- Tooth roller cutters, the teeth are made of steel-carbide alloy and welded on the cutter cone piece by piece. The teeth are highly wear resistant with hardness up to HRC64. Their lifetime is about 3 times as hard-faced tooth of milled tooth roller cutters. Cutter cones are forged with alloy steel and have high strength and rigidity to prevent them from deforming and fracturing. Tooth roller cutters are mainly used to drill soft to medium hard and abrasive formations.

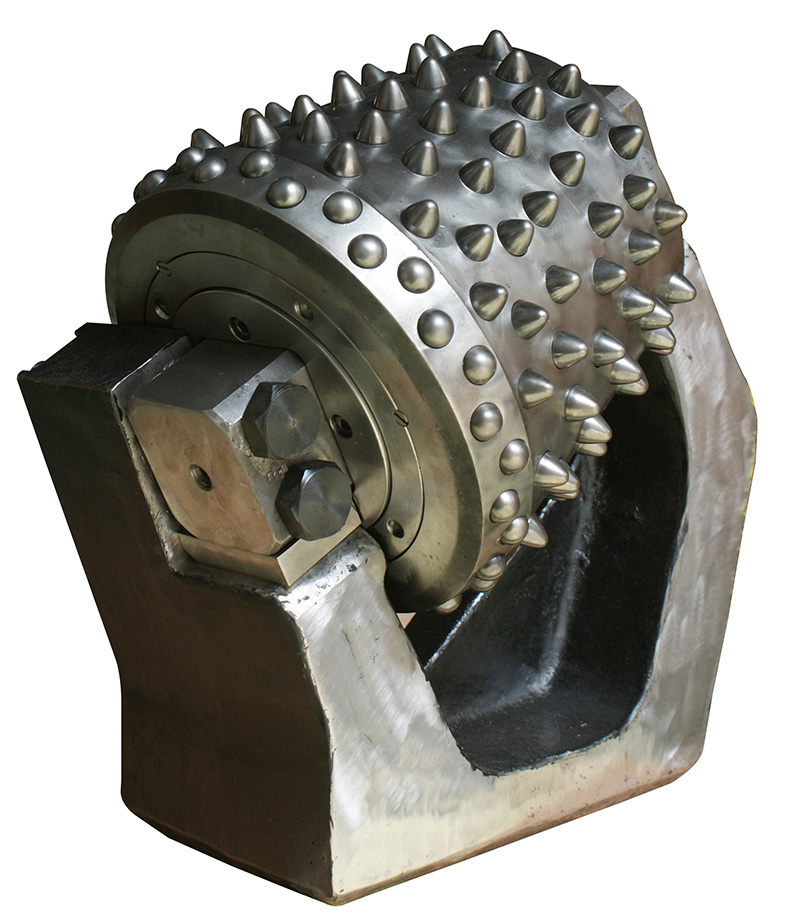

- TCI roller cutters, also called insert roller cutters, button roller cutters. Cutter cones are forged with alloy steel and inserted conical tungsten carbide tips, so they have high wear resistance and a longer service life. TCI roller cutters mainly used to drill hard and abrasive formations.

- TCI disc roller cutters, also called insert disc roller cutters, button disc roller cutters. Cutter cones are forged with alloy steel and inserted chisel tungsten carbide tips in rows, so they have high wear resistance and a longer service life. TCI disc roller cutters mainly used to drill very hard and very abrasive formations.

- Combined axial-radial roller bearings help improve the cutter operating loads, thrust force of up to 80kN for 8" roller cutters and 140kN for 12" roller cutters. Cantilever roller cutters utilize roller-ball-roller bearings, thrust force of up to 60kN for 8" cantilever cutters and 80kN for 12" cantilever cutters

- 8" roller cutters are used to drill the holes from 800mm to 1400mm in diameter, while 12" roller cutters are used to drill the holes larger than 1400mm in diameter. Cantilever cutters are arranged at the center of RCD cutter-head or used to drill holes 500-800mm in diameter.

- The pressure compensation device will be utilized in cases of high pressure.

- Maximum drilling efficiency is achieved by optimizing cutter profile and teeth or inserts arrangement.